What is Fuel Polishing and What are the Benefits?

We receive many questions from our customers about fuel polishing, so we’ve created this FAQ to support anyone considering diesel polishing as a way to improve fuel quality. Here, you’ll learn how this non-disruptive, cost-effective service can help protect your fuel, extend its lifespan and ensure optimal performance.

Don’t let contamination be the weak link in your operation. If you’d like to learn more and discuss any issues you’re having with your fuels or storage tanks, call our fuel experts today on 0330 123 1444 to get started and see how we can help you.

What is fuel polishing?

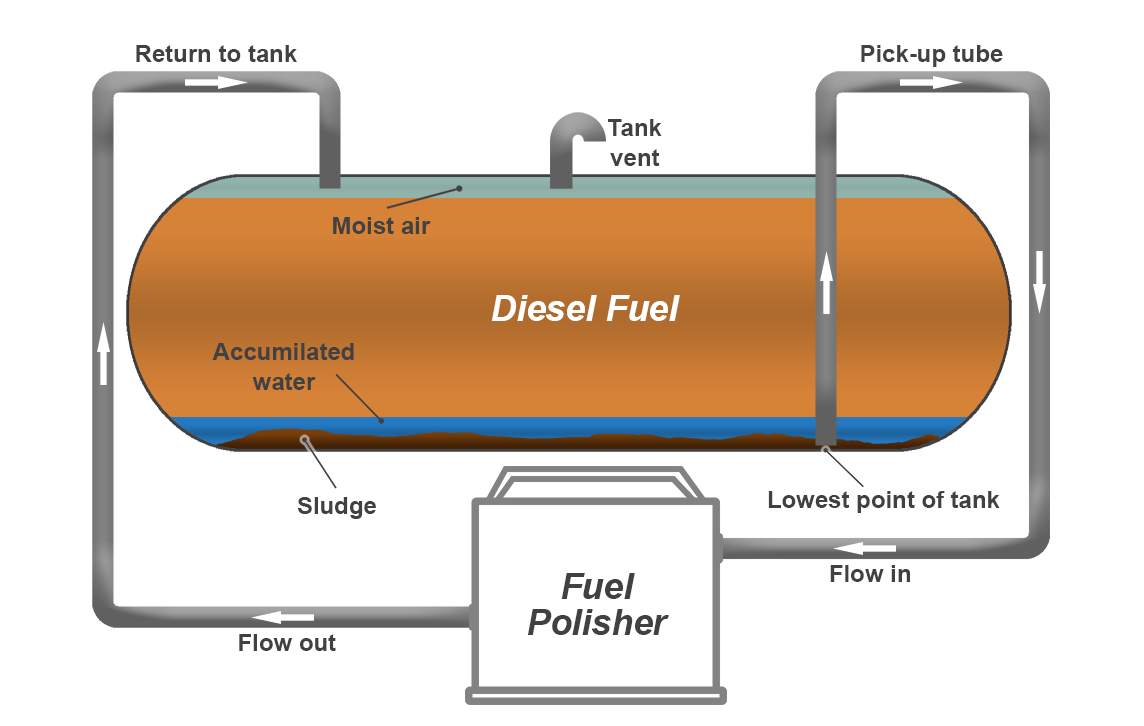

Fuel polishing is an advanced, mechanical cleaning process that removes harmful sediment through filtration and circulation, such as water, sludge and microbial contamination (diesel bug).

Fuel is removed from the tank and filtered back into the existing tank or a new tank in an optimum state, without any downtime to equipment or machinery in use.

Some of the most common fuels that we are approached to help with our fuel polishing procedures are red diesel (gas oil), diesel (DERV), biodiesel and kerosene.

Is fuel polishing necessary?

If you’ve ever experienced engine breakdown, fuel starvation, blocked filters, water or any other contaminant in your fuel, then you need a fuel polishing system. The consequence of a complete power failure could be the loss of millions of pounds in a data centre, loss of food overnight in a supermarket or, catastrophically, loss of life in a hospital.

Whatever your application (generators, storage tanks, marine vessels, etc.), fuel polishing is the simplest and cost-effective way to protect from contamination.

When fuels are stored for long periods of time, and aren’t regularly tested and treated, diesel bugs build up and cause havoc in machinery, equipment and vehicles. Diesel polishing has the ultimate goal to keep the fuel usable without having to fork out money to replace it with a new batch.

Before fuel polishing services are carried out, the fuel must be analysed and tested so that the exact problem can be identified and treated with the most appropriate solution. If it’s too severely contaminated, it’s likely that it’s not salvageable and therefore polishing would be a waste of time and money.

To determine whether your fuel needs polishing, we use a particle counter to analyse your fuel’s condition to measure any unwanted particles that have accumulated in your tank. Using a traffic light system, we’ll provide a detailed insight into its quality; green indicates that the fuel meets current legislation, amber means that the fuel is just under the required criteria and needs polishing and red, which demonstrates that an intensive fuel polishing treatment is needed.

I’m new to fuel polishing, where can I find out more?

Trying to decipher which service will best suit your requirements and budget can be daunting. We recommend booking a free site survey by the expert team at Crown Oil Environmental, who can identify any fuel-related problems and fix them with the appropriate solution.

How does fuel become contaminated?

2011 saw the introduction of revisions to the EN590 fuel regulation. This led to an increase in biodiesel content and a reduction in sulphur content to virtually zero.

Contaminants ideally need to be caught by the primary filters; however, bacteria (the most common contaminant) are generally a large biomass quantity that will quickly block filters, and if left untreated, can double in size every 20 minutes.

What are the benefits of fuel polishing?

Reduced costs – When fuel is contaminated, many people get their fuel uplifted and replaced as a quick solution. But with moderate contaminant levels, fuel can be polished and dosed with the necessary additive/biocide, which is less expensive, less wasteful and more environmentally-friendly.

Non-disruptive – Our polishing units connect to your fuel supply in a parallel fashion, so your infrastructure can carry on functioning while the supply is polished. That way, your fuel is restored to perfection without halting your operations.

Video explainer on fuel polishing

Watch our short explanatory video on our completely non-disruptive fuel polishing service to help you get the most out of your assets.

How does a diesel fuel polishing system work?

This is an advanced level filtration of fuel that is monitored and controlled using a central processing unit through a combination of depolymerisation and filtration. Fuel is passed through different equipment to progressively remove finer contaminants at different stages.

Several stages using different filter technologies are key, as a single process is not adequate to remove the solid particulates, water and wet foreign matter found.

The first stage of Crown Oil’s fuel tank polishing involves fuel being filtered through increasingly finer filters until it’s ‘clean’ and reaches a filtration level of 1 micron absolute – an industry best.

Once complete, our diesel fuel polishing unit then uses advanced depolymerising technology to break down harmful particulates to ‘polish’ your fuel to perfection.

Are all fuel polishing systems the same?

Simply put, no. Systems can filter different quantities of fuel at different rates, for example, some systems filter big quantities of fuel quickly, whereas others will filter small quantities at a slower pace.

Another difference is that there’s a huge difference in the quality of the polished fuel – many companies do not have the functionality to filter out water. Unfortunately, this means that diesel bacteria will continue to grow 260,000 times every 6 hours, leaving your expensive systems at high risk.

What affects the speed of fuel polishing systems?

Using a pump, contaminated fuel is pushed through filters; it’s harder to force contaminated fuel through a finer filter, so higher quality results usually take longer to achieve. What’s more, a system that uses higher pressure will result in more rapid filtration.

High-speed and high-quality filtration need high pressure and finer filters, meaning the larger the volume of fuel, the more powerful the equipment needed.

I add additives to my fuel; do I still need a fuel polishing service?

Additives slow fuel degradation, but they don’t completely prevent the buildup of contaminants that form in a tank. Therefore, a combination of fuel polishing and additives is needed to fully protect your fuel operation.

How will I know if fuel is sufficiently cleaned?

Water content and particle size are the two main measures of fuel contaminants.

The first indication of how effective your diesel polishing has been is to look at your fuel’s visual appearance. It should appear bright and clear with no visible signs of free water, sediment or particulate.

However, if fuel has been polished but still contains particles greater than around 5 microns, your equipment remains at great risk. Even if you can’t see any water, there will still be water suspended in the fuel itself, which will enhance bacterial growth. Water level is measured in parts per million (ppm).

Crown Oil’s fuel polishing equipment filters to below 1 micron and removes water to 100ppm – an industry best!

Will fuel polishing disrupt my business?

No, the process will cause almost zero disruption to your operations. Equipment and machinery can continue running while the fuel polishing equipment does its job, as the fuel remains in the tank while the contaminants are filtered out.

How long will fuel polishing take?

The duration of a fuel polishing service depends on a number of factors, such as:

- Tank size

- Current quality of fuel

- Equipment used

- Amount of fuel being polished

Our advanced filtration system is a fast process that removes harmful contaminants simultaneously whilst minimising our time on-site. With Crown Oil, up to 25,000 litres of fuel can be polished within 1 hour.

How often should diesel fuel be polished?

This depends entirely on the application. We recommend the process at least once a year if the stored fuel is intended for back-up power. In critical facilities such as hospitals and data centres, to ensure there’s no halt in operations, we recommend a treatment every 2 years at least.

How much does fuel polishing cost?

Due to its intricacy and involvement of highly specialised equipment, lots of people think that fuel polishing is expensive. However, it’s actually one of the most cost-effective treatments available when looking at all considerations, such as:

- No need to buy a replacement batch of fresh fuel

- Minimal disruption to services

- Avoids the cost and waste of disposing of a contaminated supply

Fuel polishing near me?

Crown Oil provides a vast range of diesel fuel polishing equipment for large and small enterprises. Our systems filter out particulates to under 1 micron, which makes us one of the only companies that reach this high level of cleaning. The quality of our equipment speaks for itself, so contact us today to learn more.

If you have any questions about our fuel polishing service, call our experts today on 0330 123 1444. We’ll be happy to discuss your requirements and answer any additional questions about fuel polishing, along with our other fuels and services.